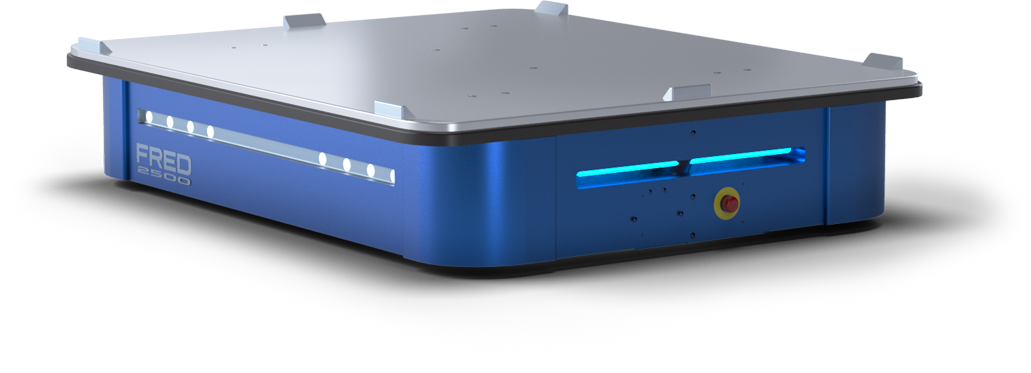

ASI Technologies, Inc. recently rolled out several exciting new features, all of which are available as optional upgrades for FRED2500, our automated material handling vehicle. Just like FRED himself, these features are simple to set up, flexible and safe, and they allow you to customize FRED for your specific environment and application. Select the options that best suit your needs to build a platform that delivers the game-changing benefits of automation.

Contact Charging

Contact Charging

Contact Charging is the next best thing to aerial refueling. Whether he’s working in a one, two, or three-shift operation, FRED now has the option of recharging whenever it makes sense for your shop. That could mean spending the entirety of any idle shifts on the charger, or scheduling stops during idle periods in more fast-paced environments. Either way, it’s easy to make sure FRED is powered up when needed. Power flows from the floor pad and plug-in charger only when they sense FRED’s presence and detect a battery that needs to be topped off. It’s even possible to install multiple charging locations at strategic spots around the warehouse in case you are not able to ensure that FRED will always return to the same area.

IR Communication

IR Communication

IR communication is ideal for automating assembly lines. With this optional feature, you can trigger FRED from an electronically generated signal, effectively letting him communicate with a computer or Programmable Logic Controller (PLC) anywhere in the shop. Setup is quick and easy—in a few minutes FRED will be ready to take commands remotely, directing him to move between locations without the need for human intervention.

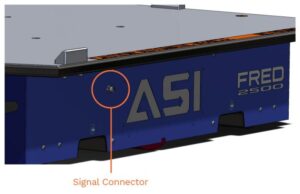

Signal Connector

Signal Connector

Our Signal Connector allows access to FREDs go buttons via third-party, onboard electronics. The option includes a four-pin connector with +24VDC power, ground, and Go forward/Go reverse command capabilities. With the signal connector in place, your system integrator can easily install the electronics needed to let FRED take direction from one or more remote sources.

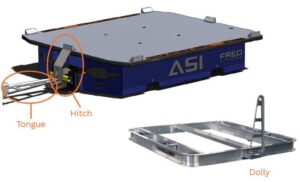

Towing

Towing

The Towing option now makes it possible for FRED to tow loads in excess of 2,500 lbs. (depending on dolly capacity). Better yet, with the towing option installed, you can quickly remove loads without waiting for a forklift. A spring-energized hitch connects the dolly tongue to FRED’s hitch, and disconnecting the two takes just the press of a release bar. It can even be operated hands-free. When you upgrade to the towing option, you also receive safety laser reprogramming to ensure safe towing.

Wireless Call / Go Button

Wireless Call / Go Button

FRED’s Wireless Call/Go Button lets the operator trigger these actions from up to 100m away. The buttons are available in various colors and come pre-programmed to trigger movement in different directions. The buttons are designed for line of sight operation, with indicator lights that flash green/yellow/red to indicate signal strength.

More Information

To learn more about any of these upgrades, or to schedule a FRED demonstration in your facility, contact ASI today. With FRED it’s never been so easy to bring smart automation into your manufacturing or warehouse environment.