The competitive pace of warehouse and manufacturing operations leaves no room for inefficiency. Ops management is constantly challenged to optimize processes for speed, quality, cost, and efficiency.

But improvements absolutely cannot come at the expense of worker safety or employee experience, especially in a hyper-competitive labor market.

That’s why the ability to automate the most tedious and least value-added tasks in a work environment is so transformative. When you can optimize processes while also enhancing workplace safety, improve worker satisfaction, and allocate valuable human labor where it can have the greatest impact, you know you have a winning solution.

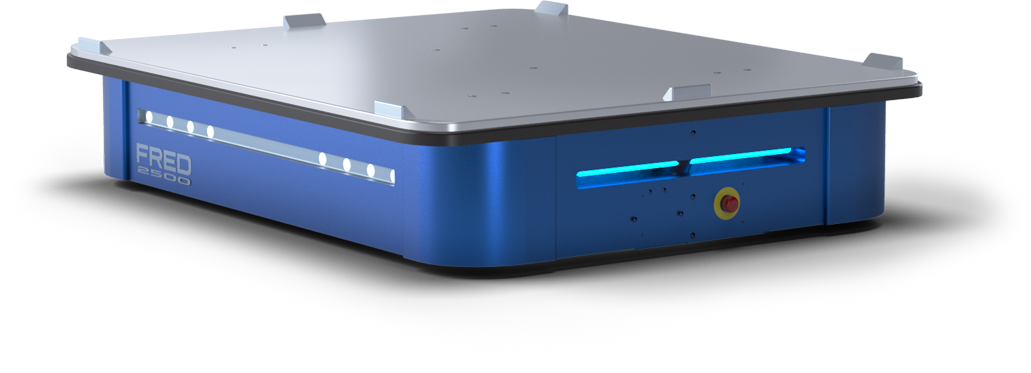

Automated guided vehicles (AGVs) like Fred are transforming operations in warehouse and manufacturing facilities by:

- Eliminating some of the most repetitive tasks from humans’ workdays

- Reducing safety risks on production floors

- Keeping environments cleaner and quieter

- Helping humans focus on work only they can do

These are our #SupplyChainGeek-approved, highest-impact recommendations for transforming operations with Fred AGV.

Replace Conveyor and Sortation Systems

Traditional, fixed conveyor systems take up a lot of space, are tough to safely move and clean around, and often contribute extra noise to the work environment.

AGVs like Fred don’t occupy a footprint; they move along a fixed path, and they’re designed to do so safely, even around fixed and moving equipment—and more important, around employees. Fred can receive product from a conveyor or packing location and deliver it to one or multiple drop-off points on its path, using modular accessories like roller tops and lifts.

In this scenario, Fred frees up precious floor space for other, more value-driven uses. Fred can be lower in cost than conveyor and sortation equipment for comparable uses.

By integrating Fred AGV, manufacturing, warehousing, and fulfillment facilities can reclaim valuable floor space for other critical operations, reduce costs associated with conveyor infrastructure, and seamlessly adapt to diverse product types and handling needs.

IDENTIFY

AGV USES CASES

Find opportunities within your own unique facilities to implement AGVs.

Revolutionize End-of-Line Product Handling

At the end of a production line—whether it’s in manufacturing or kitting in a fulfillment center—a worker is often involved in the simple movement of pallets or other bulk packaging formats. Material handling tasks like these might involve fork trucks or pallet jacks, but both options require a human. Depending on the distance goods need to move, the worker could be spending hours each day walking with a pallet jack.

It’s practically a textbook definition of wasted motion, and labor is too valuable a resource to waste.

That’s where an AGV like Fred can step in (figuratively speaking, of course) to safely and efficiently move finished products to storage or directly to shipping docks. Fred can replace bulky and often fast-moving and unpredictable equipment like forklifts. By ensuring smooth and safe product movement, Fred AGV helps maintain a steady flow of goods ready for the next production step, the warehouse, or the shipping docks.

The same goes for tasks like shrink-wrapping pallets—and for more complex or specific needs, AGVs can even be customized.

Optimize Truck Unloading and Loading

Without Fred AGV, the forklift that unloads the truck is often the same one that moves products to their next location. That’s not very efficient use of dock door time.

But with Fred AGV, forklifts pull off pallets or containers and place them directly on the AGV—and/or a pull cart—and Fred AGV moves them quickly out of the unloading area. That simple change can help transform loading docks into peak efficiency zones.

Fred AGV helps accelerate the unloading, transfers items to storage or staging areas, and reduces forklift traffic in the facility, for altogether safer and more efficient dock operations. And in the same way, Fred AGV’s capabilities speed setup for outbound shipments while minimizing the risk of accidents as well.

Automate the Mail Run

Mail runs aren’t just for mail. Done manually, routine yet critical tasks like parts deliveries, moving finished goods, and dunnage handling are around-the-clock opportunities to waste labor. But they can’t go undone; clean, well-stocked workstations are a must for efficient operations.

Mail-run style loops throughout a facility are an ideal use of AGVs, and this one’s easy for Fred AGV. Fred simply follows the loop along a predefined path to ensure continuous delivery of components to workstations, disposal of dunnage, or whatever else needs to move, keeping everything running smoothly.

Workers aren’t tasked with the tedious tasks, which means they can focus on more satisfying, high-value tasks without the frustrating, inefficient downtime spent waiting for (or moving) parts.

Make Operations More Efficient and Worker-Friendly

Adding AGVs to warehouse and manufacturing operations is a strategic move toward a more efficient, safer, worker-centric future. It’s not just about replacing outdated, inefficient equipment with flexible, easy-to-implement material moving and handling options.

Fred AGV consistently and almost instantly demonstrates the power of smart automation to transform operations in more ways than efficiency. AGVs help create work environments that prioritize employee safety and job satisfaction. As the industry continues to evolve and face new challenges, embracing elegantly simple innovations will be key to staying competitive.

Click here or below to explore the automation opportunities Fred AGV can bring to your operations.