The future is automated—and it has wheels. It’s also happening right now in the manufacturing and warehouse industries. These businesses are more often turning to automated guided vehicles (AGVs) to carry the heavy loads once hauled by industrial vehicles.

If you’ve been considering adding this kind of automation to your warehouse or distribution center, you’ll want to review these six ways to integrate the automation technology into your operations smoothly, and win the hearts of new generations and legacy employees alike:

- Appeal to a new generation of workers

- Get seasoned veterans on board

- Promote the safety benefits

- Emphasize productivity boosts

- Offer training and flexibility

- Show off AGV capabilities to build enthusiasm

1. Appeal to a New Generation of Workers

Younger generations are used to technology’s omnipresence in their lives. What they may not realize is that almost all workplaces, even in bedrock industries like warehousing, are taking steps to modernize their facilities.

Chances are good that new incoming workers will be ready to embrace automated technology. In fact, simply having such technology in the first place may make a workplace more attractive to new hires. It demonstrates a forward-thinking perspective that’s a fit for our fast-paced world.

One way you can add even more appeal for the younger generation (and seasoned veterans who want to spice up the workday) is gamification. Put some stakes in the processes, such as points, challenges, and other game-inspired ways to stir up some friendly competition.

Once the staff is fully trained on AGVs, you can create leaderboards to showcase efficiency, productivity, and safety. This can help foster a sense of accomplishment in a way that’s fun and familiar.

2. Get Seasoned Veterans On Board

Some employees may be more accustomed to driving a forklift to relocate cases of products rather than interacting with AGVs that follow magnetic tape. It’s possible they’ve perceived automation as problematic in the past, and their resistance to change can have roots in previous experiences. Change is sometimes difficult, but it’s often good—especially workplace technological advances.

TOP 10 AGV

MYTHS DEBUNKED

Get the Facts on Automated Guided Vehicles

Involve your legacy employees early. You may want to start slow with just one AGV before adding more. This could be a great time to convince them that an AGV actually augments their jobs. It can perform some of the more dangerous or physically demanding tasks, allowing your workers to focus on more rewarding, value-added duties.

And don’t hesitate to ask for their wisdom. Many workers appreciate the chance to serve as a mentor and may jump at the opportunity to learn the AGV so they can train new coworkers.

When your seasoned veterans are on board, they’ll fire up the new generation about what’s possible.

3. Promote the Safety Benefits

Forklifts were listed as the source of 70 work-related deaths in 2021 and 7,290 non-fatal injuries involving time away from work in 2020.

Implementing even one AGV in a warehouse can help mitigate the risk of injury across your operations. If an AGV falls between a loading dock and a semi while transporting materials, the vehicle may be damaged. But that scenario still prevents injuries to human workers. If a stack of products tips onto an AGV, you’d need to dig out the AGV and assess the damage, but you don’t have to worry about the operator of the vehicle getting hurt—or worse—in that calamity.

Safety is of critical importance. Protect your workers, and promote this protection.

Handing over the riskiest tasks to a machine sends a strong message that you value your workers’ health and safety.

4. Emphasize Productivity Boosts

Once the AGV is ready for use, you can expect to see gains in productivity. You can likely anticipate increased throughput, better unit load times, and your workers’ availability to conduct more complex tasks.

AGVs can operate 24/7 and with only minimal breaks to perform basic maintenance, or charge or swap batteries. They’re able to reduce product damage that may occur as the result of human error while driving. And if you’re short staffed, they can fill in the gaps. AGVs take up less space than conveyors or human-operated fork trucks, so they can help free up space for more storage, distribution, or production lines.

These are all helpful characteristics of AGVs that make for a more efficient, smooth, and positive work environment.

5. Offer Training and Flexibility

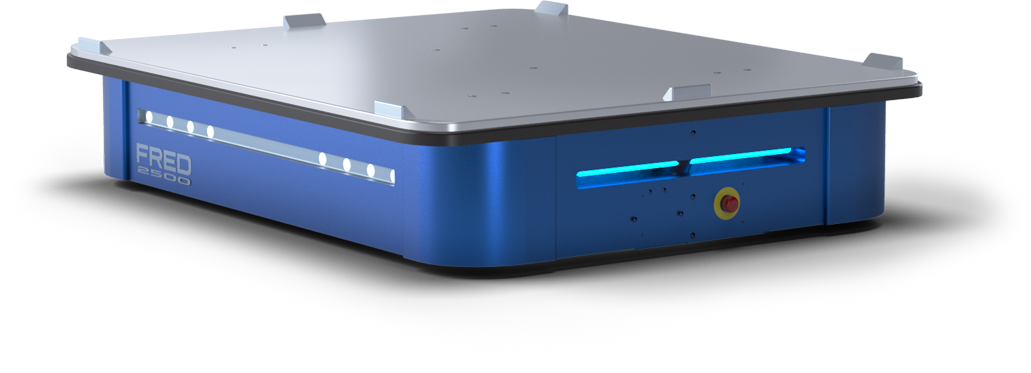

Most AGVs are easy to train on. Fred, our own AGV, requires no software and can be learned in just hours. Hands-on training is crucial for employees to feel at ease, so allow time for your employees to learn the ins and outs. Let them get well acquainted and comfortable with this machine as a new tool—and maybe even as a new teammate.

And don’t forget to accommodate different learning styles. Be inclusive and ensure everyone is able to feel confident in the training they receive.

6. Show Off AGV Capabilities to Build Enthusiasm

You’ll also want to show off everything AGVs offer. Give plenty of demonstrations of Fred so all workers can see that Fred:

- Only takes 2 hours to set up

- Doesn’t require WiFi

- Adjusts to infrastructure changes

- Has a compact footprint

- Can carry up to 2,500 pounds

- Can tow up to 5,000 pounds

- …and more

Our YouTube channel has plenty of demo videos you can share as well. This one’s a real-world auto-wrap and conveyor scenario:

And, perhaps most exciting of all, anyone on staff can maintain it with a bit of training. This is automation that adds to the workplace—and joins the team rather than taking away from it.

Learn the Truth About AGVs

Whenever something new comes along, there’s bound to be a lot of chatter—and plenty of falsities. That’s why we created a useful guide that debunks some of the old myths about AGVs and reveals the fresh truth behind this evergreen technology.