Automated Guided Vehicles (AGVs) like Fred are now practically indispensable in industrial settings like manufacturing and warehousing. These self-navigating machines are streamlining processes and minimizing labor costs as they roll.

As AGVs take on the tedious, redundant, and heavy loads, what do they leave in their wake? For starters, AGVs offer:

- Empowering first experiences with automation

- More predictable production planning

- Safer industrial work environments

- Reduced labor and operational costs

- More efficient and more profitable operations

But before you hop aboard the AGV train, it's really important to understand that there’s no one-size-fits-all automation solution. Some work areas, conditions, and tasks are better suited to other automation solutions—and in some instances, you still need your human manual workers.

If you’re considering an AGV, use these questions to help assess whether an AGV is an ideal solution and a good fit for your unique operational needs.

Seven Questions to Guide Your AGV Decision

1. How is Your Current Workflow Structured?

Before assuming an AGV is where you’re headed, assess your existing operational landscape. Are human operators using forklifts, or is a conveyor belt system already in place? Understanding your current setup can provide valuable insights into what needs improvement and whether AGVs can offer a viable solution.

2. What Material Handling Methods are Currently In Use?

The techniques used for loading and unloading products and materials can significantly influence the suitability of AGVs. If your operations require delicate handling or precise placement, could human intervention be more effective?

3. What are the Dimensions and Weights of Items Being Moved?

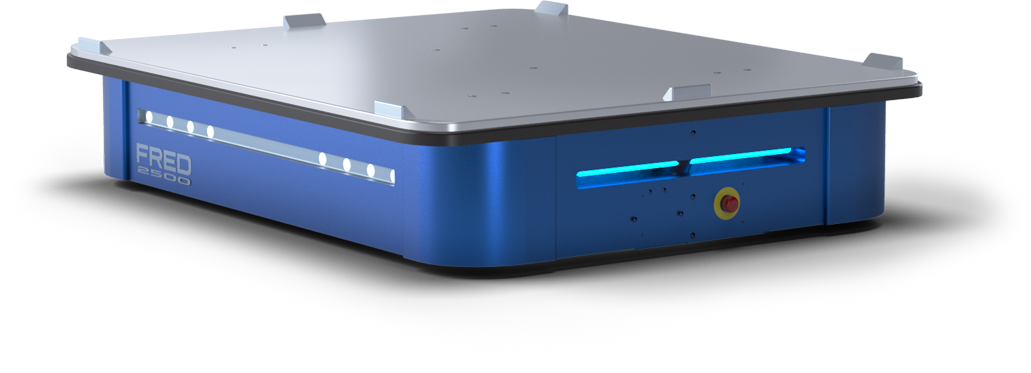

Every AGV has its own payload capacity and limitations. If your facility deals with oversized or heavy items, be sure to verify capabilities on any AGV you’re considering.

4. What Level of Automation is Required?

That’s right, we’re going there: full automation isn’t always the best course of action. Could a semi-automated system, where AGVs work in tandem with human operators, help you find a balance between efficiency and flexibility?

5. In What Environmental Conditions Will AGVs Need to Operate?

Environments such as cold storage, high humidity, wet conditions, or extreme heat all present specific challenges for any equipment, and this is also true for AGVs.

6. What is the Operational Tempo?

The density and speed of your operations can also influence the suitability of AGVs. In high-density, fast-paced settings, self-navigating automation solutions may not be capable of working at the desired speed for optimal efficiency.

7. What Unique Limitations and Challenges Lurk in Your Facility?

Sometimes, you really need an expert to take a walk through. An experienced systems integrator can reliably recognize potential pitfalls and vulnerabilities you simply might not see: that gently graded ramp, for example, could still be too steep for many AGVs. Dense forklift traffic can also present a challenge.

Take an Informed Approach to Automation and AGVs

Judicious use of AGVs can boost operational efficiency in valuable ways. But no one technology or solution solves every material moving challenge.

Getting the experts in for a conversation early in your evaluation process can help you get to your end goal faster and with less risk of wasted time and resources. Look for a partner to help—preferably with a wider range of automation experience, and not someone whose eggs are all in the AGV basket. You may discover that, for your use case, another solution is better. Maybe it’s autonomous mobile robots (AMRs), a fixed system, or maybe people are still your best bet.

But by carefully considering your answers to seven questions above, you'll be better equipped to make an informed decision about whether AGVs are the right fit for your specific operational landscape. A professional assessment and a pilot program can also offer invaluable insights into the most effective automation solution for your facility.

As you sort through it all, you’re likely to encounter enthusiasts and detractors for every technology option. A word of caution: Lots of folks’ awareness and perspective on AGVs is decades-old and, at this point, totally out of date. We recommend you update your knowledge, and we made it easy with our free infographic. Click below to download and keep rolling toward your automation goals.