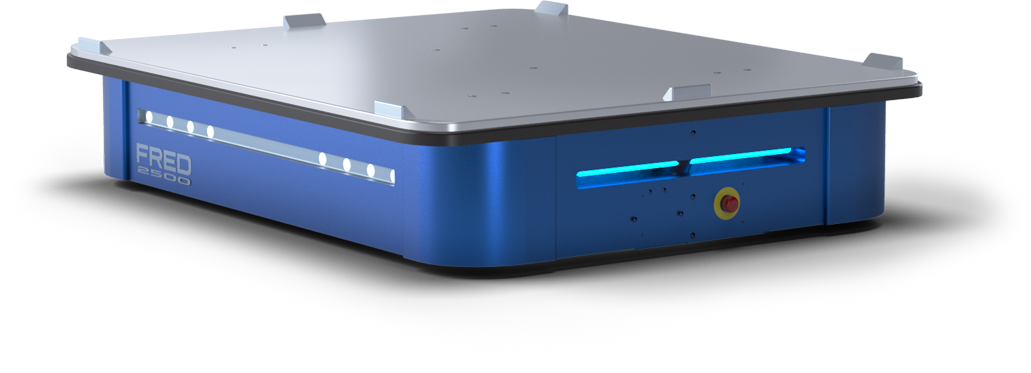

More and more, businesses of every size—and across nearly every industry—are turning to AGVs to solve their material-movement challenges. And that makes sense. The many benefits AGVs bring to the warehouse or factory floor cannot be achieved without them. What’s more, the financial barriers to entry to this type of automation have dropped significantly over the past few years. FRED, ASI’s heavy-duty AGV, for example, costs only $35,000. Just five years ago, a less capable vehicle could easily cost twice that. FRED can now even be rented for only $1,000 per month.

What do you get with an AGV?

- Increased Productivity

- Increased Safety

- Increased Flexibility

- Increased Use of Existing Square Footage

- Increased EOL Efficiency

- Decreased Labor Costs

- Decreased Exposure to Labor Shortages

- Decreased Product Damage

- Quick and Predictable ROI

We’ve previously written other articles detailing each of the benefits above. Today, these benefits add up to a razor-sharp competitive edge for AGV newcomers. This edge, combined with affordable pricing, is why so many SMEs are now integrating material-movement automation into their logistics. But what’s a competitive edge today will be table stakes tomorrow. It won’t be long before you’ll be hard-pressed to find a successful business operating a warehouse or factory without an AGV presence. These vehicles are following a course of adoption similar to that of desktop computers. In the 70s, an office computer was a novelty. In the 80s, it was an advantage typically reserved for only the largest players. And by the 90s, it was the cost of doing business—for companies large and small alike.

Today, AGVs are still the advantage computers were in the 80s (but often without the significant financial barriers to entry). To avoid getting caught behind the curve, now is the time to investigate their potential for your business. But not every AGV is right for every operational scenario or circumstance. Before making the decision to invest, you should be prepared to ask these questions of yourself and your AGV vendor.

1. What do you want to accomplish?

Answering this broad question will help you narrow down your search. Where all AGVs excel is predictable, repetitive material movement. Do you want to automate order picking? End of line (EOL) processes? Raw-material or parts movements to different assembly lines? Where in your workflow you’ll harness an AGV’s advantages will help you determine which type is right for you.

AGVs come in three basic form factors :

- Unit Load

- Typically used to transport pallets, single products or raw material (e.g., a steel coil)

- Often the best option for carrying loads to and from conveyors, EOL equipment (e.g., pallet feeders, palletizers, stretch wrappers, checkweighers, etc.), loading docks and automated storage and retrieval systems (AS/RS)

- Can often be customized with onboard lifts, conveyors, rolling carts, etc. for additional functionality

- Tugger

- Typically used to tow a train of non-motorized vehicles

- More limited in functionality

- Not as many customization options available

- Forklift

- Used to fully replace a forklift or pallet jack

- Accomplishes horizontal and vertical material movement

- Not as many customization options available

Of these basic form factors, you’ll find variations of each—along with some crossover in functionality. FRED, for example, can act as a unit load vehicle carrying up to 2,500 pounds or a tugger towing a train of up 5,000 pounds.

2. How much weight do you need your vehicle to carry or tow?

After determining which form factor meets your needs, you’ll need to determine the maximum load you expect your vehicle to carry or tow. You’ll have a rather broad range to choose from. A unit load AGV might be designed to nimbly transport just a few hundred pounds. Some tuggers, meanwhile, can tow well over 100,000 pounds.

FREDDiE, ASI’s small, medium-duty AGV, can carry up to 400 pounds. FRED can carry over six times that weight. If you don’t need your vehicle to carry loads heavier than 400 pounds, then an AGV like FREDDiE is the more economical option.

FREDDiE, however, hasn’t been designed to tow, while FRED has. So, while considering material weight, you’ll also want to consider how the material needs to be transported. Perhaps an individual load may be only 200 pounds. But if you wanted to tow three, five or ten loads at once, then a dedicated tugger or a multi-functional AGV like FRED would make more sense.

3. How customizable is the AGV?

You may ask your AGV to do one thing, and one thing only. But that doesn’t mean an AGV’s ability to be modified or customized won’t be important to you. In fact, you might end up adjusting your workflows based on customization options.

Some AGVs, for example, can be modified with a surface-mounted conveyor. You might request this modification to have your AGV automatically transfer product to and from a checkweigher before moving on to a robotic palletizer. Or, you might use FRED to entirely replace a traditional fixed conveyor.

Other common modifications include lifts (for ergonomics), quick-release hitches (for towing applications) and bolt-on carts, as seen in this video of FREDDiE. Attaching a cart to FREDDiE in this way turns the AGV into its close cousin, the AGC (Automated Guided Cart).

4. Is your facility set up for wireless connectivity?

And if it isn’t, are you willing to make that investment in IT and infrastructure? AGVs vary in complexity and navigation systems. If required to communicate with the cloud—or a local control system—the vehicle will need access to some sort of wireless connectivity. Bluetooth has limited range. WiFi has more range, but can still struggle in larger environments. GPS may not work indoors at all.

If your facility isn’t set up for wireless connectivity—or if you don’t want the hassle, expense and potential disruption of maintaining such a system—then look for an AGV that won’t require it. As have some other AGVs on the market, FRED and FREDDiE are designed to operate fully independently of other systems They can be modified with on-board electronics that do communicate. But they’re also ready to operate out of the box.

5. What kind of navigation technology can your facility accommodate?

This question goes hand in hand with the last. Some navigation technologies will require wireless connectivity. Others may require significant modifications to your facility. The most common navigation technologies include:

- Magnetic

- Spot: Cylindrical magnetic spots are embedded in the floor.

- The AGV follows a CAD drawing uploaded to its onboard computer, and uses magnets to recalibrate its steering angle as it operates.

- Installation will likely need to be performed by your vendor.

- Rerouting will require new CAD drawings and help from your vendor.

- Tape: A strip of magnetic tape is laid on the floor.

- The AGV follows only the magnetic tap (including markers to tell it where to stop or change direction).

- CAD drawings are not necessary.

- No vendor assistance required for installation or rerouting.

- Optical: A strip of colored tape (or a painted line) is laid on the floor.

- The AGV’s optical sensors follow the colored line, making CAD drawings unnecessary.

- No vendor assistance required for installation or rerouting.

- If the tape or paint becomes worn, it will cause navigational problems.

- Laser: Reflectors are mounted around your facility.

- The AGV uses an onboard laser to triangulate its position in relation to the reflectors.

- The AGV must always be within line of sight of three reflectors to accurately navigate. Reflectors must be kept clean.

- Installation and rerouting will require vendor assistance.

- LiDAR: A form of “natural navigation” that requires no external infrastructure.

- The AGV maps its surroundings using sensors during training runs, and stores the data onboard.

- Installation and rerouting is technically free, but may require vendor assistance with CAD drawings.

- Complex and expensive technology.

- Could have trouble in chaotic or variable warehouse/factory environments.

- Spot: Cylindrical magnetic spots are embedded in the floor.

Each of the technologies above is ordered from least to most expensive, either for installation cost or AGV cost. LiDAR, for instance, requires no infrastructure so installation is technically free. But the AGVs themselves are far more expensive than those that follow magnetic strips, and may also require costly software maintenance agreements.

6. How often do you expect to change your AGV’s route?

There isn’t one single navigation technology better than the rest. Each has its advantages. But your AGV’s navigation technology will determine ease and cost of rerouting. If you expect to experiment with routing or occasionally change your workflows, then you’ll be best off with an AGV that either follows a magnetic strip or uses LiDAR.

We designed FRED and FREDDiE to follow a strip of magnetic tape because it’s flexible, accurate, affordable and makes for incredibly quick and easy installations without requiring vendor assistance. In fact, you can install or reroute FRED within two hours. And while not free, additional magnetic tape will never break the bank as it costs roughly $1 per foot.

You may also at times want to temporarily change an AGV’s movement patterns. Magnetic tape makes that easy and affordable, too.

LiDAR is also flexible and accurate, and technically “free” to reroute, requiring no external infrastructure. But if your connected AGV requires a maintenance agreement, then you’ll always be paying that cost. The vehicles themselves can also be anywhere from three to ten times more expensive than a similarly capable magnetic-strip guided AGV.

7. How much can you afford to spend?

Just like automobiles, the costs of AGVs vary widely (anywhere from $20,000 to hundreds of thousands of dollars). But unlike automobiles, you may have noticed it’s hard to find pricing on manufacturer websites. The reason for that is likely to avoid sticker shock. Without a sales rep to help guide your decision, you might see that an AGV costs $60,000 and decide now isn’t that right time for you to invest. Another reason it’s so hard to find online pricing is because you’ll likely need to purchase more than the AGV itself. What kind of ongoing vendor maintenance agreement will an AGV require, for example?

FRED and FREDDiE are some of the few AGVs available with pricing you can find online. That’s partly because we designed their pricing structures to be as straightforward as the vehicles themselve. And it’s also because they’re affordable—there’s no sticker shock.

8. Does your vendor offer a RaaS program?

RaaS (Robots as a Service) programs were designed to help SMEs enter the AGV market at minimal upfront cost. If you’re not familiar, RaaS is roughly the equivalent of renting an AGV. And it can completely eliminate all financial barriers to entry for warehouse or factory automation.

FRED and FREDDiE are both available with RaaS pricing models. This is what each looks like:

FRED

- 1,000 per month

- 6-month commitment

- $30,000 buyout option after six months

FREDDiE

- $750 per month

- 6-month commitment

- $16,500 buyout option after six months

A RaaS rental program allows you to test the waters with material-movement automation at a very low cost. That’s a huge benefit if you’re new to automation or AGVs. Because a RaaS rental is temporary, you can have peace of mind while exploring automated productivity. This is a great way to determine if an AGV is right for you. And if it is, you can turn your rental into a buyout.

9. What do you expect in terms of ROI?

Now that you’re investigating AGVs, you’ve undoubtedly encountered the promise of a quick ROI. Virtually every manufacturer claims their technology will deliver blazingly quick returns. But what does a quick ROI really mean? Three years? Two years? Eight months?

In a previous article, we calculated the return FRED could deliver when compared to a forklift. It turned out to be around four months. And that was if you were to purchase FRED upfront. Under a RaaS pricing model, you’d see even greater financial efficiencies and quicker returns.

Discuss ROI with your vendor, and be clear about your expectations.

10. Do you know how to start? We’re Here to Help.

ASI’s AGVs may be perfect for your needs. Or, they may not suit your facility or workflow.

There could be questions you should be asking your vendor that we’ve not included in this article. We’re available to talk through your challenges and opportunities, and help make sure you’re asking the right questions and getting the right answers, whether from us or another vendor.

Ultimately, we’re interested in propelling warehouse and factory automation forward. We’ll help you make your decision—even if it’s not to purchase one of our AGVs.

Automation Questions?

Businesses across many industries are now turning to automation technologies as powerful solutions to once unforeseeable material-movement challenges. We’re here to help you navigate the automation landscape, and drive your business forward. To learn more about how FRED and FREDDiE provide easy-to-implement solutions to complex challenges, contact an ASI Automation specialist today at info@fredagv.com.