2020 has (most likely) been the most eventful year that most of us can remember. To say that the way we work and approach work has changed would be an understatement. As COVID-19 continues to affect communities around the world, we must learn to rethink the way we approach safety in the workplace on a whole new level: the tiniest one. As dangerous as industrial accidents can be, it’s an invisible virus that can truly bring a company to its knees.

So what can we do? It’s the question that’s driven some truly innovative answers over the last year, from remote working solutions to managing work shifts. And though we didn’t develop AGVs specifically to help with social distancing, we’ve come to realize that they can be immensely helpful when it comes to productivity levels during COVID-19. They not only handle work that once needed human labor, they can help maintain a safe distance between people in your work force. And if you are considering investing in an AGV, now might be the best possible time to do so.

Gaining Ground, Bouncing Back

The adaptation of AGVs was gaining rapid traction prior to 2020. From 2015-2020 the industry grew by 25.5% in the US alone.1 How is the market doing now that the year is drawing to a close? Well, it depends on how you look at it. When the nationwide quarantine first went into effect, the delays in business cost the industry $450 million in revenues. But according to a new report2 from interactanalysis.com the sector will bounce back, doubling by 2021. And with the move to e-commerce and reduced dependence on human labor, that bounce back will be substantial.

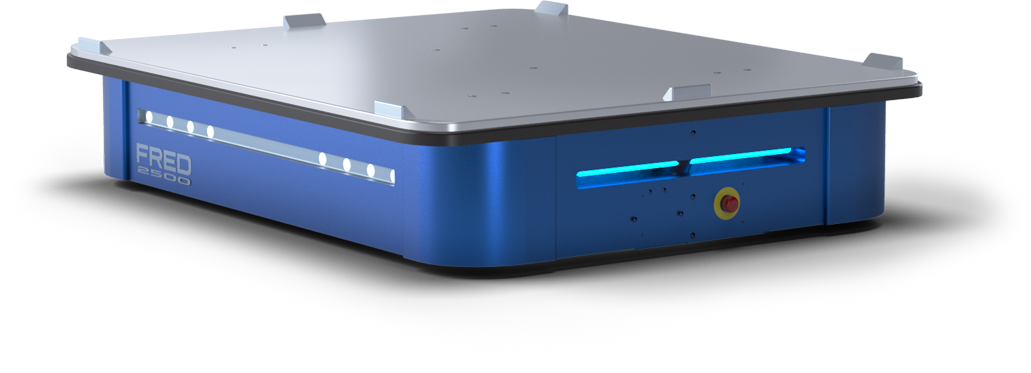

Changes in workforce and work procedures aren’t going anywhere soon, and for the bigger AGVs, this is bad news. The more complex the AGV, the bigger the impact due to loss of human workforce. A complicated piece of machinery is going to need programming and backup, two things that require humans. On the flip side, the pandemic has created openings for simpler, low-cost AGVs, especially those with rental options. Enter FRED and FREDDIE. These versatile, low-cost AGVs are the ultimate solution to quickly scale up operations in an environment where human labor is limited and often dangerous, while keeping employees socially distant and safe.

Capabilities for a Changing World

FRED and FREDDIE are simple, adaptable, reliable and affordable. With an easy-to-install magnetic tape, your whole system can be up and running in about two hours. Path adjustments are even quicker and easier than initial setup, meaning the labor required is minimal. It doesn’t use WiFi, GPS or Bluetooth, so there’s no need for extensive IT. In fact, FRED and FREDDIE don’t need programming or software maintenance agreements at all, and it’s built like a tank so it requires minimal physical maintenance.

FRED/FREDDiE’s low price point means you won’t have to sacrifice human labor for robotics. But it’s capabilities mean you can if you need to. These capabilities include:

- Predictable Material Movements

Using FRED or FREDDiE eliminates the need for a third person to handle the material, which reduces the chance they can spread germs throughout your facility.

- Automate EOL Processes

Depending on your set up, FRED and FREDDiE can also automate your existing End-of-Line (EOL) processes. A quick-to-implement example of this would have FRED or FREDDiE (a) make a stop at a palletizing station (robotic or manual), (b) move on to a semi- or fully automatic stretch wrapper and then (c) carry the wrapped pallet to your loading dock.

- Reduce Strain on Existing Workforce

It’s not uncommon for two or more workers to manually carry goods from point to point. Social distancing, however, now leaves that task to just one person. Depending on your product, this could be a bigger task than one person can handle—but even FREDDiE (our smaller option) can handle up to 400 lbs.

- Make Staggered Shifts More Productive

In an effort to abide social distancing guidelines, many businesses have taken it upon themselves to introduce staggered shifts. An AGV like FRED or FREDDiE is designed to work around the clock, only taking the occasional break to recharge. Otherwise, it can work alongside your employees 24/7/365, easing their workloads while increasing their productivity.

The New Normal

We are far from knowing everything we need to know about COVID-19. But we’re almost 100% sure that robots can’t catch it. FRED and FREDDIE are able to work side by side with any employee without needing a single day off. The AGV market is projected for huge growth in the coming years for reasons that go beyond just a trend toward automation, but because they are flexible and scalable enough to respond to changing needs and the sudden need to adapt.

The pandemic hit us all suddenly, and left an indelible mark on society. We’re doing everything we can to get back to normal, but we also know that “normal” has changed. With FRED and FREDDiE: you can adapt quickly and adeptly to changes in your workspace, meaning that it’s more than just an investment in productivity, it’s an investment in safety and responsibility—and stay on the forefront of how we work in the future.

Automation Questions?

Businesses across many industries are now turning to automation technologies as powerful solutions to once unforeseeable material-movement challenges. We’re here to help you navigate the automation landscape, and drive your business forward. To learn more about how FRED and FREDDiE provide easy-to-implement solutions to complex challenges, contact an ASI Automation specialist today at info@fredagv.com.

1IBIS World

2 Ash Sharma, “Covid-19 Will Eliminate $0.5 billion Mobile Robot Revenues in 2020, but Market Predicted to Nearly Double in 2021,” Retrieved from interactianalysis.com