If you’ve done any research on automated guided vehicles, you may notice that the terms AGV and AMR are used frequently, sometimes they’re even used interchangeably—for a reason. They are both forms of automation, so when talking about the automation industry as a whole, they’ll use either/or. They have a lot in common, as they are used for similar tasks and functions. However, they aren’t the same kind of machine, and sometimes the differences can be vast. Keep reading for more information on the similarities and differences between AGVs and AMRs, as we help you decide which one is right for you and your workspace.

Businesses of nearly every size and industry are turning to automation to increase efficiency and productivity. No matter which kind you choose, it will free up workers to focus on more important tasks. They both move items and components around a factory floor or nearly any kind of workspace. But the two have some major differences, and are not interchangeable. The main difference between the two is that AGVs are automated vehicles that follow a set path, while AMRs are actual robots that can navigate freely. Beyond that, there are other differences, as we’ll outline below.

AMR

Let’s start with AMRs—robots that can move freely. Sounds pretty futuristic, right? Well, it’s a little more complicated than a Jetsons-esque robot helper friend. AMRs contain sensors and software that help them navigate around an area. Digital “maps” are generally programmed into their system so they can learn the area and move around freely (Unfortunately, they won’t make you breakfast). AMRs require technology that generally needs to be programmed by professionals, and also requires professionals for troubleshooting. The more the AMR can do, the more complicated the programming, and the more chance you’ll need to call in outside help. While they may seem simpler than AGVs because they don’t require tracks, AMRs tend to be more costly due to the (sometimes proprietary) technology used on each one.

AGV

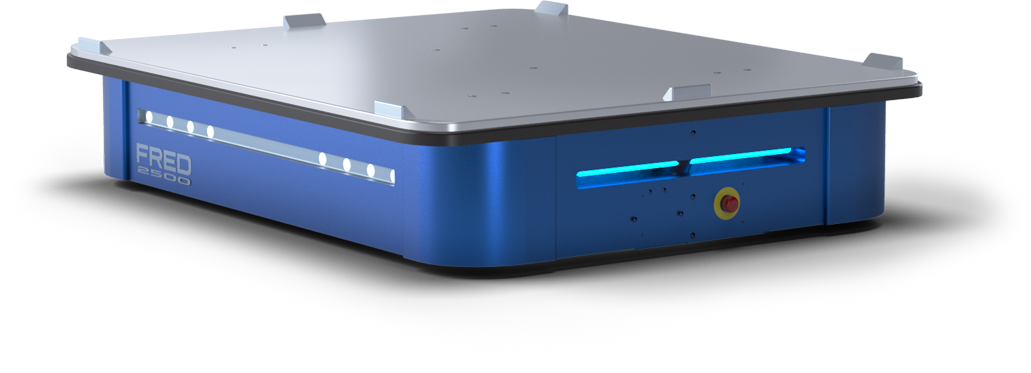

AGVs are far more common than AMRs, mostly because they’ve been around for longer. They move along predetermined routes via a variety of navigation systems, depending on the type of and size of the AGV. For instance, FRED and FREDDiE use magnetic tape placed along the route. One of the common misconceptions about AGVs is that their routes are hard to adjust, which may be true for some of the older, bulkier models. We designed FRED/FREDDiE’s tape to be easy to install and move around. They also don’t require any specialized technology in order to navigate the area, so you can be up and running in less time than an AMR. FRED and FREDDiE are so simple to use that you won’t even need a specialized IT professional to maintain the software. And while some of the larger AGVs can be more expensive, FRED and FREDDiE were designed to be available at a lower cost, meaning they’re accessible to more people.

Provided that they’re performing the same function, the choice between an AMR and AGV usually comes down to ROI. FRED and FREDDiE can pay for themselves in just four months and save owners over $100,000 per year. A similarly capable AMR, meanwhile, might cost as much or more than FRED/FREDDiE save in a single year.

The easiest way to consider the differences between AGVs and AMRs is by comparing them to trains and self-driving cars. An AGV follows a predefined path from which it will not deviate (just as a train follows tracks). An AMR—while still typically following a predefined path—can deviate should the need arise (just as a self-driving car may navigate around an unexpected obstacle). In practice, the difference is subtle. Should a person or other obstacle block an AGV’s path, it will come to a stop and wait for its path to be cleared before resuming. An AMR in the same situation may instead attempt to navigate around the person or obstacle.

For most warehouses and factories, an affordable—and capable—AGV like FRED and FREDDiE would be the smartest first step toward automated workflows. They’re simple to set up and operate and simple to move around, making you more competitive in the market, faster. You’ll be more competitive in the market as you leverage new productive efficiencies. And you’ll be ready for more collaborative automation when the time is right.

Automation Questions?

Businesses across many industries are now turning to automation technologies as powerful solutions to once unforeseeable material-movement challenges. We’re here to help you navigate the automation landscape, and drive your business forward. To learn more about how FRED and FREDDiE provide easy-to-implement solutions to complex challenges, contact an ASI Automation specialist today at info@fredagv.com.