Spend any amount of time in the manufacturing industry and you’ll probably hear a lot about Automatic Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs). AGVs/AMRs are becoming so common that industries outside of manufacturing and distribution are starting to consider them as options—they are popping up in retail, healthcare and other sectors. And while automation may seem complicated and futuristic, AGVs/AMRs are actually relatively simple machines designed to perform basic tasks that can bog down human labor.

AGVs can be excellent options for your work space, as they provide many benefits besides simply reducing the cost of labor. They can increase worker safety by operating in unsafe areas, and feature built-in mechanisms that go beyond the measures that can be taken by human operators. AGVs are also an asset when it comes to expansion, as they can free up space for additional manufacturing lines or warehousing. Last, but far from least, they can be productive 24/7, which can greatly improve output.

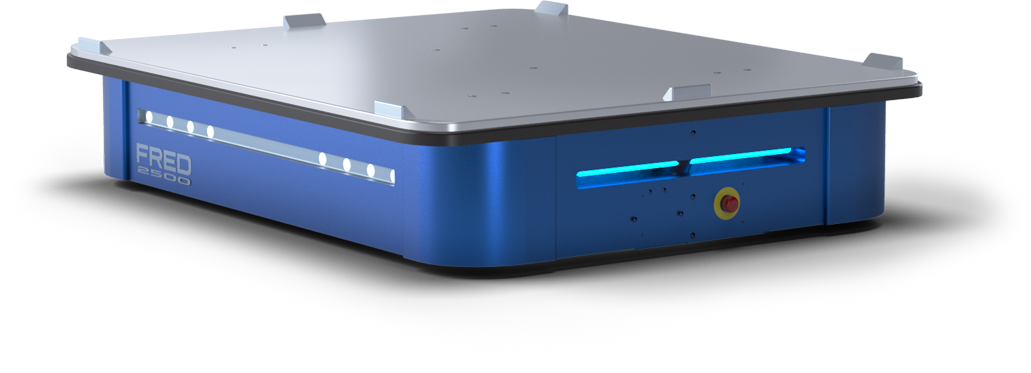

Despite all this, there are still a lot of misconceptions about AGVs. These include the false belief that the initial investment is too much, the assumption that the programming and software maintenance are complicated, and the presumption that AGVs aren’t flexible or scalable once installed on the factory floor. But like any entrepreneur, FRED Automation set out to disrupt; to use the misconceptions as a starting point for developing our latest innovations in AGV technology: FRED and FREDDiE.

Misconception #1: Initial Investment is Too High

Cost of entry is a huge barrier in the world of AGVs. Now more than ever, finances are tight and few can afford to drop hundreds of thousands on a machine, no matter how helpful it might be. This was the starting point for FRED Automation. We wanted to make an AGV that’s more than just automated, but accessible. And even though FRED and FREDDiE are half the cost of most AGVs, they are seriously heavy-duty. Out of the box, FRED is capable of carrying up to 2,500 pounds and towing up to 5,000 pounds, and FREDDiE can carry up to 400 pounds. They follow an easy-to-install magnetic tape path, so the route can be laid and even reconfigured in under two hours. What’s more, because neither FRED nor FREDDiE require a wireless connection, complex programming or even any software, their installation costs are negligible.

Even the most expensive AGVs deliver relatively quick ROIs. In fact, the right AGV can save over $100,000 a year. Imagine how quickly your return can be if you only spent half that cost.

Misconception #2: AGVs Will Replace Humans

“Robots will someday replace the human workforce” is a myth we’ve been hearing since the beginning of the robotics industry. The truth is that machines will never fully be able to operate without humans. In fact, AGVs can reallocate humans to tasks that provide more value to the company by eliminating the need for workers to perform repetitive, mundane, and even difficult jobs.

The tasks that factory floor robotics perform are predictable and often strenuous. For instance, palletizing is enormously strenuous for humans, causing both mental and physical stress, which is why we’ve seen automatic palletizers at work in factories and warehouses since the 1950s. FRED/FREDDiE continue to take the strain off humans, made even more accessible by the lower price point—meaning you won’t need to sacrifice worker pay to install your AGV.

Today’s AGVs can efficiently collaborate with robotic palletizers. For example, FRED virtually eliminates every hard and soft cost associated with traditional pallet movement. They can compensate for labor shortages and reduce material damage. AGVs follow a predefined path; FRED/FREDDiE will follow its magnetic tape path to your robotic palletizer, wait as a pallet is formed, and then be on its way with up to 2,500 pounds of material. There are never any surprises.

And a safe, predictable environment is better for everyone: robots and humans.

Misconception #3: AGVs Decrease Flexibility and Scalability

One of the benefits of a human workforce is flexibility; they can jump from task to task without having to reset programs and processes. This is why AGVs are usually designed to augment human flexibility instead of getting in the way of it. Automation is not an all-or-nothing venture—AGV systems can be installed to cover as much or as little of the work space as deemed necessary. For example, FRED/FREDDiE’s path is as easy to change as it is to install to compensate for surges in operation.

AGVs are built with flexibility in mind—even more so with a system like FRED/FREDDiE. They’re designed to fit your specific space, and are extremely simple to set up, use, and maintain.

Misconception #4: AGVs aren’t easy to Introduce into Existing Environments

As we mentioned earlier, a lot of people think of AGVs as something that’s all-or-nothing—that your workspace is either automated or not. In reality, that’s pretty far from the truth. Most workspaces have at least some automation in them, and scaling up or down on the amount of automation is easier than it has ever been.

When we set out to make FRED/FREDDiE, we wanted to make them remarkably easy to set up and integrate. In fact, setting up the magnetic tape should only take around two hours. They do not use WiFi, GPS or Bluetooth so connectivity is a cinch, and there won’t be any programming or IT integration. And while our options are easier than most other AGV systems, no system should alter your existing environment so extensively as to not make them worth the investment.

Automation For All

Automation may not be 100% right for everyone, but it can be accessible to anyone. When we developed FRED and FREDDiE we sought to alleviate the common misconceptions about AGVs that still stand in the way of automation, and often in the way of productivity. Whether you’re worried about cost of entry or fear of integration, there are options that will fit your facility—because even though they perform relatively simple and repetitive tasks, AGVs are remarkably flexible and customizable.

Automation Questions?

Businesses across many industries are now turning to automation technologies as powerful solutions to once unforeseeable material-movement challenges. We’re here to help you navigate the automation landscape, and drive your business forward. To learn more about how FRED and FREDDiE provide easy-to-implement solutions to complex challenges, contact an ASI Automation specialist today at info@fredagv.com.