There are many different types of AGVs across varying sizes, strengths, and uses. They all have one thing in common, though: they all run on some kind of battery power. The type of battery they use depends on the size and kind of navigation system of the AGV and on the AGV’s battery charging system. In this article we’ll discuss the three main kinds of batteries: GEL/AGM, lithium, and pure lead; and the three main kinds of charging solutions: opportunity charging, battery exchange and standard plug-in method. Which one is right for you? Keep reading to find out.

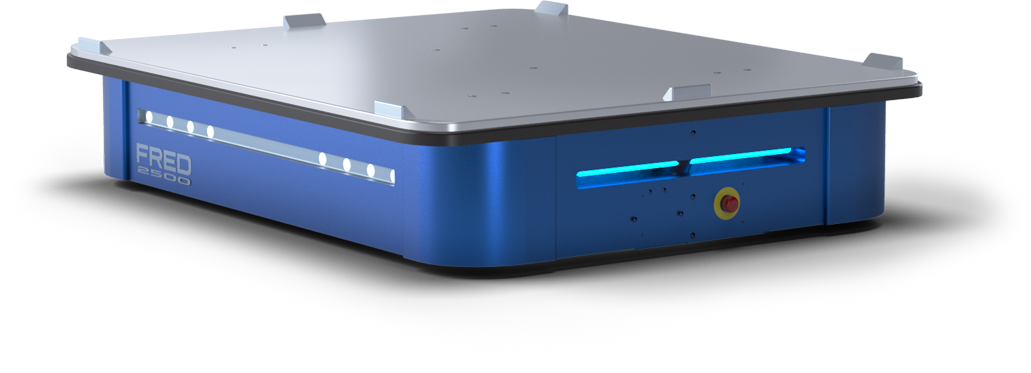

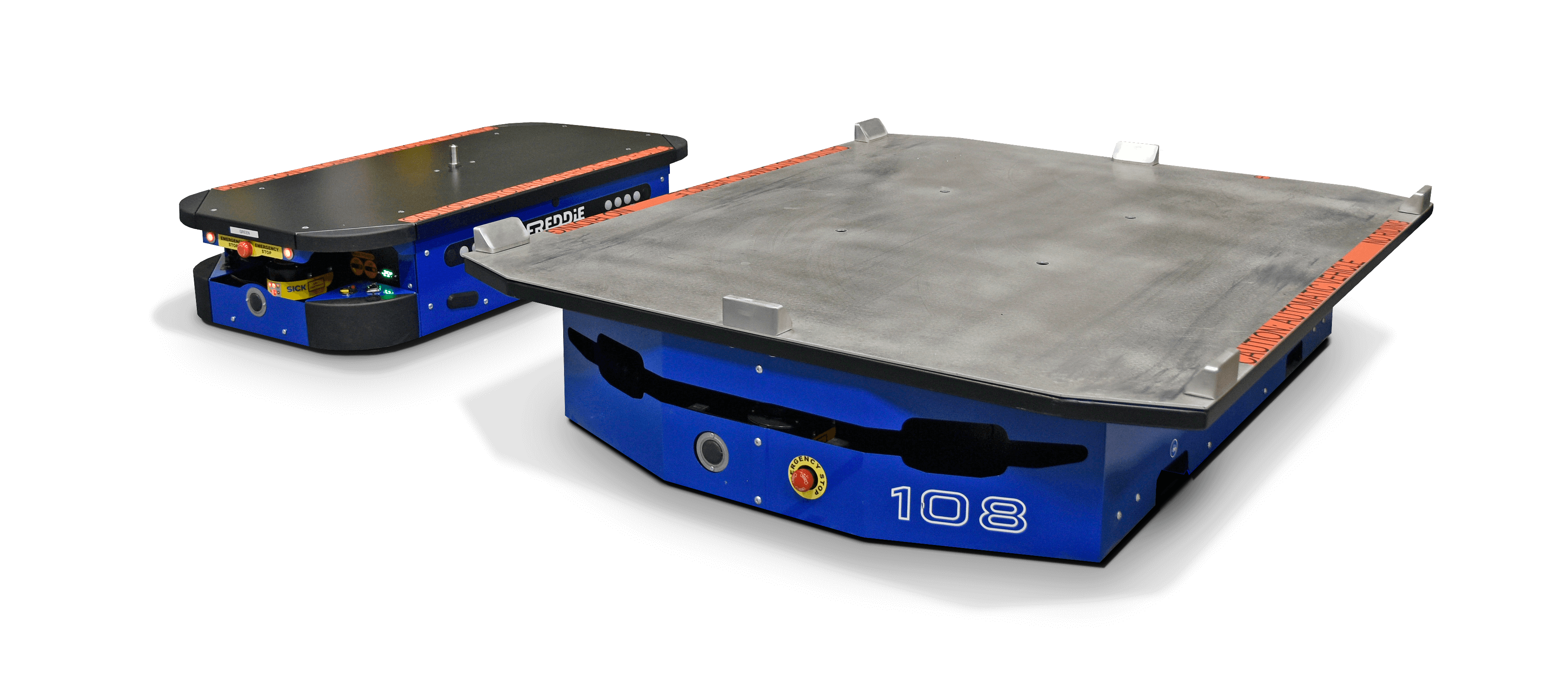

First, let’s get into the batteries themselves, starting with GEL/AGM. These are widely-used in the AGV industry because they are sealed and non-spillable, do not need maintenance, produce no emissions, and can be transported safely. The AGM battery used by FRED and FREDDiE, for instance, stands up well to low temperatures and can charge up to five times faster than the flooded lead acid versions (more on them in a moment). These kinds of batteries can also deep cycle, meaning they produce a large, rapid amount of power when and where you need it.

Pure lead batteries use (as the name suggests) pure lead thin plates as their main source of power. They have excellent battery life and support short, fast recharging. However, they do emit a low amount of gas when recharging, meaning they aren’t suitable for all conditions. They also cost more than standard GEL/AGM batteries, but are far cheaper than lithium batteries.

Speaking of lithium, they are the final entry in our battery triumvirate. Lithium technology is relatively new, and the cost is 4 to 5 times higher than an AGM or pure lead battery. They do last longer and can be much more powerful than other types of batteries, but they are unstable and require much more maintenance to keep safe and working. Lithium may become the standard battery of the future, but as it stands right now its technology keeps transforming, meaning you’ll have to keep buying more parts to keep up.

Though it’s good to know what kind of battery your AGV is using, it’s the charging situation that will probably have a bigger impact on what kind you choose and your day-to-day operations. There are three main charging solutions: battery exchange, opportunity/contact charging and standard plug-in method.

Battery exchange is exactly what the name implies: once one battery runs out, it’s exchanged for another, etcetera and so on. This means that the machines can work constantly, as the exchange itself usually takes less than three minutes. Once the battery gets used to a certain level, it goes to a predetermined area where it’s substituted for a new one, either by a human or an automated process. Which brings us to our first disadvantage of battery exchange: it requires extra labor on the part of the workforce, in that someone always needs to be available to perform the exchange. There are also machines that can perform the task, but they have historically been very expensive.

The other charging solution is known as opportunity, or contact charging. This means that the AGV stops and recharges the battery by itself whenever it is needed, or whenever it has free time. The more AGVs you have working at one time, the more charging stations there will be. Just like human shifts, some AGVs work while the others “rest and recharge.” This is ideal if you don’t have an operator available to perform battery exchange—for instance, the night shift at a warehouse. And though batteries for contact charging can be expensive, they don’t have to be: like FRED and FREDDiE.

FRED and FREDDiE are among the most affordable AGVs on the market, including the batteries and the charging station. FRED/FREDDiE’s contact charging includes a collector mounted on the side of both machines, a floor pad and a plug-in charger.

This kind of charging is ideal in a 3-shift operation, so that FRED and FREDDiE spend the majority of their idle time on the charger. That could mean spending the entirety of any idle shifts on the charger, or scheduling stops during idle periods in more fast-paced environments. Either way, it’s easy to make sure FRED is powered up when needed. Power flows from the floor pad and plug-in charger only when they sense FRED’s presence and detect a battery that needs to be topped off. It’s even possible to install multiple charging locations at strategic spots around the warehouse in case you are not able to ensure that FRED will always return to the same area. With contact charging, you never need to worry about keeping FRED or FREDDiE juiced up and ready to go.

That’s just a quick overview of the most common kinds of AGV batteries and charging solutions. Of course every AGV will be different and require its own unique kind of charging capabilities. We think that FRED and FREDDiE are among the most versatile choices you could make for your workspace, but what’s right for you will be determined by your facility and your needs.

Automation Questions?

Businesses across many industries are now turning to automation technologies as powerful solutions to once unforeseeable material-movement challenges. We’re here to help you navigate the automation landscape, and drive your business forward. To learn more about how FRED and FREDDiE provide easy-to-implement solutions to complex challenges, contact an ASI Automation specialist today at info@fredagv.com.