When’s the last time you used the phrase “social distancing”? Probably not very long ago. And when’s the first time you used that phrase? Also, probably not very long ago. What was virtually an unknown concept at the beginning of March 2020 (according to Google Trends) has now fully rooted itself in the popular lexicon. We live in a COVID-19-era world. And that means we now live in the age of social distancing.

Just as the concept of social distancing probably wasn’t top of mind for most at the start of the COVID-19 pandemic, neither were AGVs. But as businesses worldwide seek every opportunity to protect their bottom lines and workforces, AGVs are now seen as investments that can safeguard both. Unlike most other investments in factory and warehouse equipment, AGVs pay for themselves extraordinarily quickly. They’ve also proven immune to many of the business challenges posed by COVID-19—not the least of which is the need for social distance.

Social Distancing Has the Potential to Hamper Productivity…But the Alternative is Worse

In our COVID-19 world, maintaining social distance isn’t just a pervasive recommendation. It’s often the law. That poses a challenge for manufacturers and warehouses. How can you remain as productive as you were pre-COVID-19?

To enforce social distancing on the warehouse or factory floor may impact your productivity. But choosing not to enforce it certainly will. Businesses that skirt mandated social distancing risk an outbreak that would not just impact productivity, but would force the company to come to a grinding halt.

Social distancing isn’t just key to slowing the spread of COVID-19. For manufacturers and warehouses, it’s key to staying in business.

Productivity at a Distance

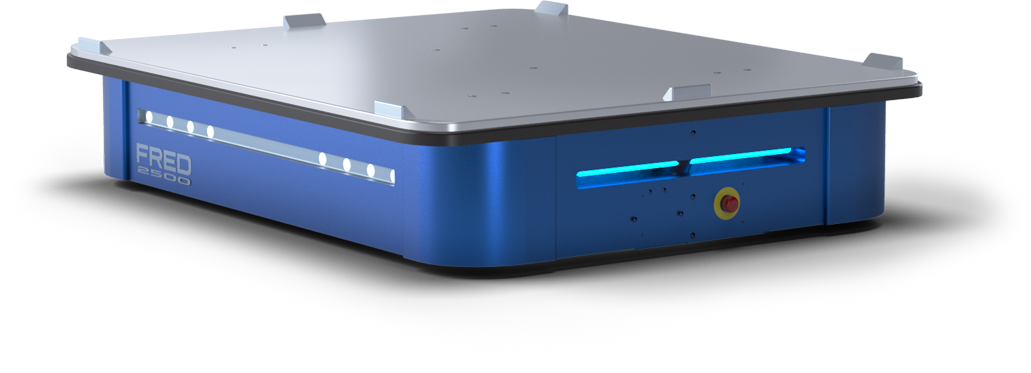

Warehouses and manufacturers need innovative answers to the productivity challenges posed by social distancing. For many businesses, AGVs have provided those answers. They can decrease—or even eliminate—the otherwise potentially devastating impact of enforced social distancing. To demonstrate, we’ll use ASI’s AGVs, FRED and FREDDiE, as examples.

In more ways than one, FRED and FREDDiE bring you opportunities to practice social distancing on the manufacturing or warehouse floor while remaining as productive as possible.

1. Predictable Material Movements

- Most material movement is predictable. FRED and FREDDiE can easily transfer material from person to person. This would be a very basic Point-A-to-Point-B implementation. But using an AGV eliminates the need for a third person to handle the material, which reduces the chance they can spread germs throughout your facility.

- An added benefit of this implementation is that it clears up usable square footage. That’s costly real estate you can put to more productive use.

2. Automate EOL Processes

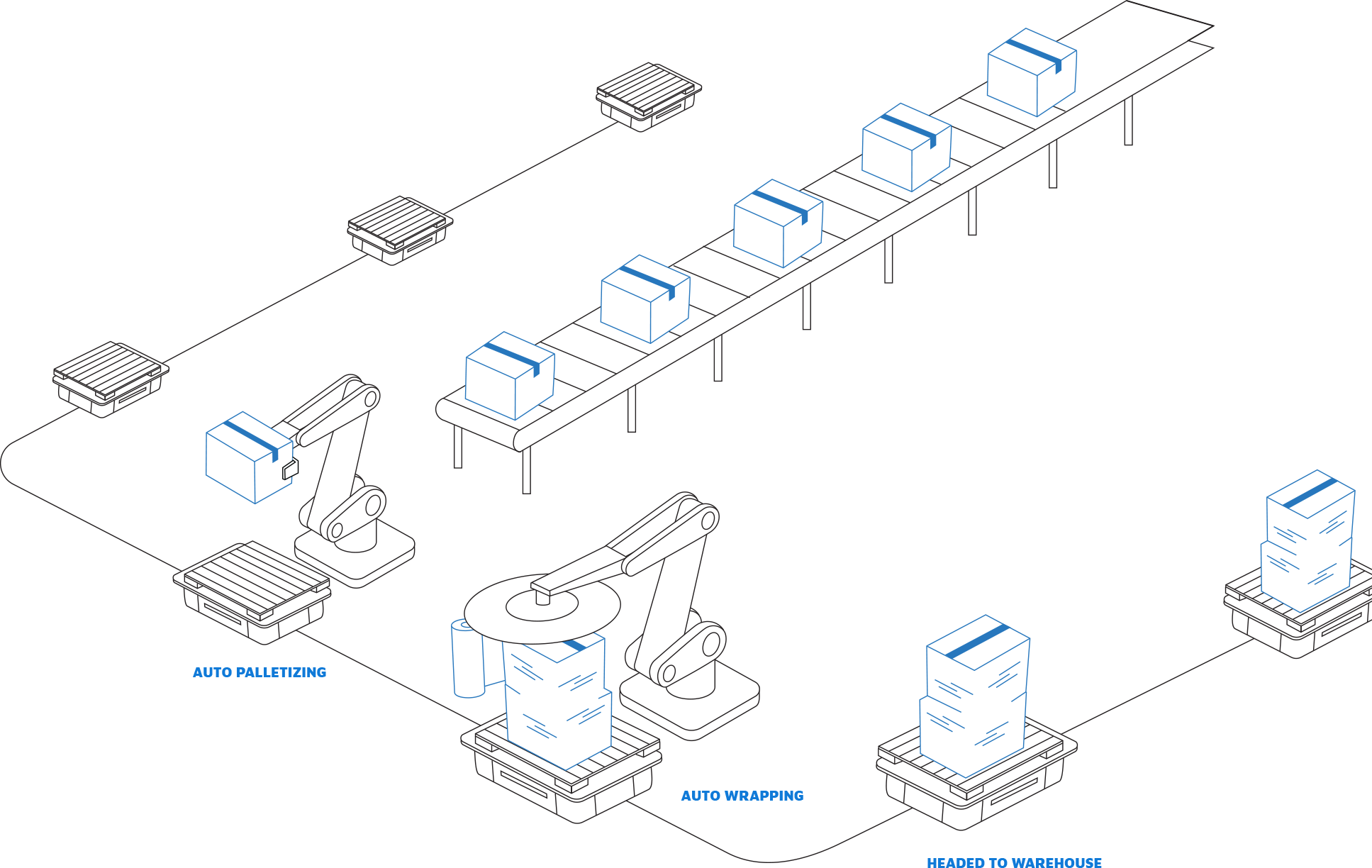

- Depending on your set up, FRED and FREDDiE can also automate your existing End-of-Line (EOL) processes. A quick-to-implement example of this would have FRED or FREDDiE (a) make a stop at a palletizing station (robotic or manual), (b) move on to a semi- or fully automatic stretch wrapper and then (c) carry the wrapped pallet to your loading dock.

3. Reduce Strain on Existing Workforce

- Even at facilities with forklifts, conveyors or other types of material-moving equipment, it’s not uncommon for two or more workers to manually carry goods from point to point. Social distancing, however, now leaves that task to just one person. Depending on your product, this could be a bigger task than one person can handle.

- But it’s a task most AGVs can handle easily. Even ASI’s smaller, medium-duty AGV, FREDDiE, would have no trouble with a 400 lb payload. Under these circumstances, FREDDiE would not only allow for productive social distancing, it would significantly reduce both the risks—and associated costs—of worker injury and product damage.

- A final benefit of this use of AGVs is the reduction of product handling. The more products are handled by humans, the more opportunity for COVID-19 to spread—inside and outside your facility.

4. Make Staggered Shifts More Productive

- In an effort to abide social distancing guidelines, many businesses have taken it upon themselves to introduce staggered shifts. But for facilities that don’t already operate around the clock, this concept can take its toll on both personnel and productivity.

- An AGV like FRED or FREDDiE, however, is designed to work around the clock, only taking the occasional break to recharge. Otherwise, it can work alongside your employees 24/7/365, easing their workloads while increasing their productivity.

These four examples of “productivity at a distance” illustrate how an AGV can solve many of the inherent challenges in a post-pandemic world. Each not only protects your employees from overwork and exposure to COVID-19. They protect your business and bottom line.

AGVs in the Age of Social Distancing

AGVs have answered the question nobody ever thought they’d ask just a few short months ago: How can we remain productive while practicing social distancing?

These robots weren’t designed to promote social distancing. But as a result of their design, that’s exactly what they do. More than investments in productivity, AGVs are investments in safe and responsible productivity. And because of that, they may be what drives our nation’s warehousing, manufacturing and distribution/logistics industries forward in a post-COVID-19 world.

Automation Questions?

Businesses across many industries are now turning to automation technologies as powerful solutions to once unforeseeable material-movement challenges. We’re here to help you navigate the automation landscape, and drive your business forward. To learn more about how FRED and FREDDiE provide easy-to-implement solutions to complex challenges, contact an ASI Automation specialist today at info@fredagv.com.