“Whether you’re working in a manufacturing plant, DC or warehouse, how you move product from point A to point B will impact your operation’s throughput, efficiency and bottom line. In the right application, AGVs can redistribute workers to value-added positions, improve safety and material tracking, and reduce product damage and labor costs. AGVs can also be introduced without the need for plant modifications and are flexible enough to adapt to an operation’s changing business needs.”

With rapid changes to the global economy, product redesigns and ever-changing technologies, manufacturers require solutions that can rapidly respond to these changes. Traditional conveyors do not adapt to these changes and provide little flexibility in flow or process. Hence, the rise of assembly line AGVs.

AGV paths are defined by either magnetic tape or geolocation. Between these options, there is no simpler solution than magnetic tape. Paths can easily be redefined by rapidly re-applying tape to the floor without IT intervention.

“Magnetic navigation for various light-duty AGVs typically uses magnetic tape for the guide path. One major advantage of using tape instead of wired guidance is that it can be easily removed and relocated if the course needs to change. It also removes the expense involved in restructuring the floor of the factory or warehouse.”

– isa.org

Space Utilization: AGVs vs. Conveyors

Automated Guided Vehicle usage is also on the rise because of smaller and flexible space utilization. The typical AGV has a much smaller footprint than a conveyor, freeing up much needed space in the assembly line. Conveyors are expensive, inflexible and impede travel throughout the plant. Do conveyors make sense in today’s ever-changing, agile world? The answer is often no. Organizations using conveyors find themselves forced to work around the system. Traditional conveyers limit manufacturers ability to truly be Lean. Conveyors also tie up a significant amount of inventory and power, while AGVs work on an as needed basis.

When comparing the two options, it is important to carefully consider cost and flexibility—for now and the future.

Safety

Workers compensation claims, lost productivity and large lawsuits are significant risks for manufacturing organizations. Investments that improve workplace safety are good for employees and the bottom line. According to Travelers Insurance, more than 100,000 workplace injuries occur in the manufacturing sector in the United States each year. Almost 50% of those injuries are related to overexertion, slips and falls or repetitive motion. While direct expense costs—such as medical and rehab—are known, there are underlying costs that can be equally or more disruptive to an organization.

- The loss of an employee with specialized skills

- The need for temporary, quality workers

- Downtime

- Administrative costs

AGVs can limit the risk of repetitive motion, slip and fall and overexertion injuries by providing the heavy lifting and transport.

- AGVs move slowly

- They have lights and beep, alerting team members to their presence

- They have safety lasers to immediately stop if something or someone is in their path

“The automated guided vehicle (AGV) market is driven by several advantages… it has resulted in lesser on-site mishaps and assured workforce safety.”

The Assembly Line Automated Guided Vehicle, a Simple, Flexible and Safer Solution

The current skilled labor shortage combined with constant change requires manufacturers to take a new look at old processes. AGVs can free up capital to attract and retain the right talent. Plus, they can change as the organization’s processes change. However, many manufacturers are still reluctant to invest in this technology because it is viewed as difficult to set up and maintain. Furthermore, the ROI can be daunting.

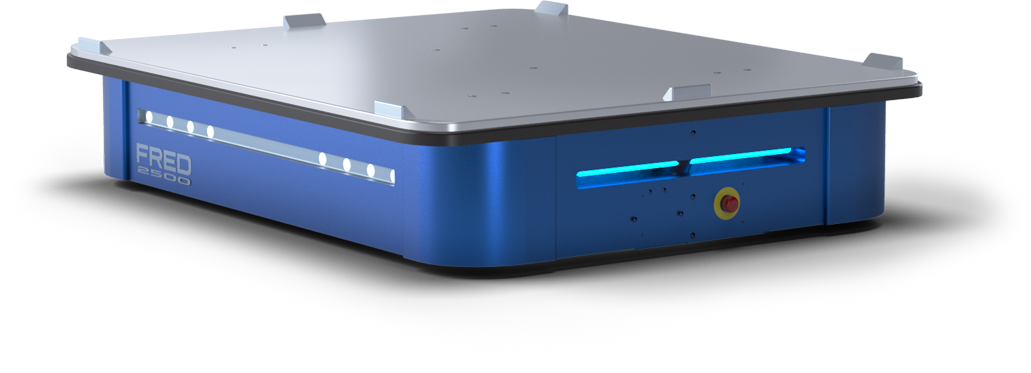

However, with AGVs like the FRED 2500, set up is simple and can often be done in about an hour. Plus, FRED requires no IT support to change its path. Its safety features keep your team safer and its compact size requires less floor space than a conveyor. Find out the ROI on FRED and then contact us for a demo in our facility or yours.