Features

& Benefits

Barcoding's AGVs make it easy to automate your workflows, so you can boost your facility’s productivity, safety, and bottom line.

Learn more about Fred now!

Simplicity

Compared to other AGVs, Fred is remarkably easy to set up, use and maintain.

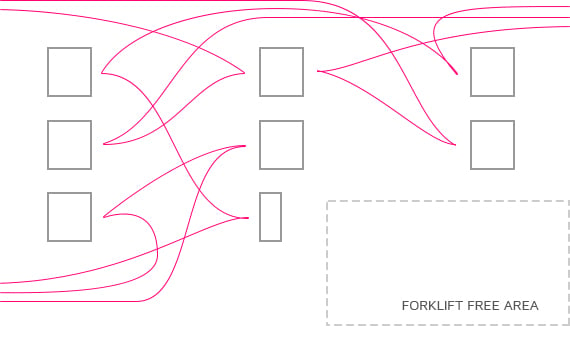

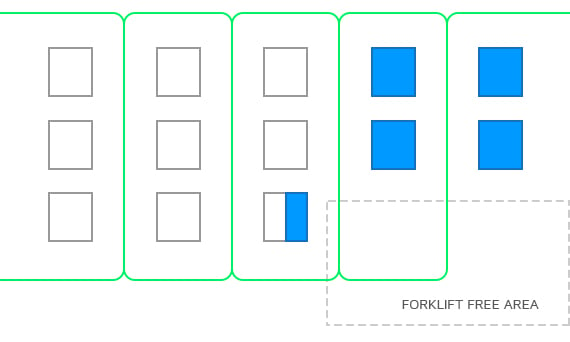

- Guided by easy-to-install magnetic tape

- Path adjustments are even quicker and easier than the initial setup

- Doesn’t use WiFi, GPS, or Bluetooth, so there are never any connectivity issues or hacking concerns

- No programming, expensive IT support, or software maintenance agreements required

-

Other Robots (& AMRs)

Other Robots (& AMRs)

-

Simple, efficient setup

-

Automated charging

-

Requires limited ongoing ITUnlikely

-

Requires no WiFi, GPS, or Bluetooth (but can be connected)

-

Can be maintained by existing personnel

-

Limited upfront capital investmentUnlikely

Productivity

Fred AGVs are mobile productivity powerhouses that create new opportunities for efficiency in your facility and among your workforce. And both drive near-instant business results thanks to the quickest ROIs you can find from any AGV on the market.

- Works hard and without breaks 24/7/365

- Reduces product and facility damage caused by human transport

- Solves labor-shortage issues and employee-training investments

- Frees up significant space for additional manufacturing lines or warehousing

- Stuck moving materials

- Inefficient use of time

- Unstimulating work leaves little opportunity to problem solve

- Constrained by labor shortages

- New labor more expensive to onboard, train & license

- Often needs to work overtime

- Redeployed to more valuable tasks

- Focused & productive use of time

- New opportunities for stimulating

work & problem solving - Freed up despite labor shortages

- New labor less expensive to onboard, train & license

- Enjoys desired work-life balance & more productive shifts

Flexibility

Compared to conveyors, forklifts, pallet jacks, and tuggers, Freds are extremely flexible in its ability to solve your challenges.

- Works in nearly any warehouse or indoor space to serve many applications

- A variety of customizable ways to move goods on- and off-platform

- Manage a multitude of load types with up to 2,500 lb carrying or 5,000 lb towing capacities

- Reconfigure paths at any time to free up floor space or change projects

-

CONVEYOR

CONVEYOR FORKLIFT

FORKLIFT PALLET JACK

PALLET JACK

-

FootprintCompactVery LargeModerateModerate

-

Customization EaseHighLowModerateModerate

-

Carrying Capacity (FRED)Up to 2,500 lb.5,000 + lb.2,500-6,000 lb.Up to 11,000 lbs

-

Towing Capacity (FRED)Up to 5,000 lb.N/AN/AN/A

-

Ties Up PersonnelNoNoYesYes

-

Automated EOL IntegrationYesYesNoNo

Durability

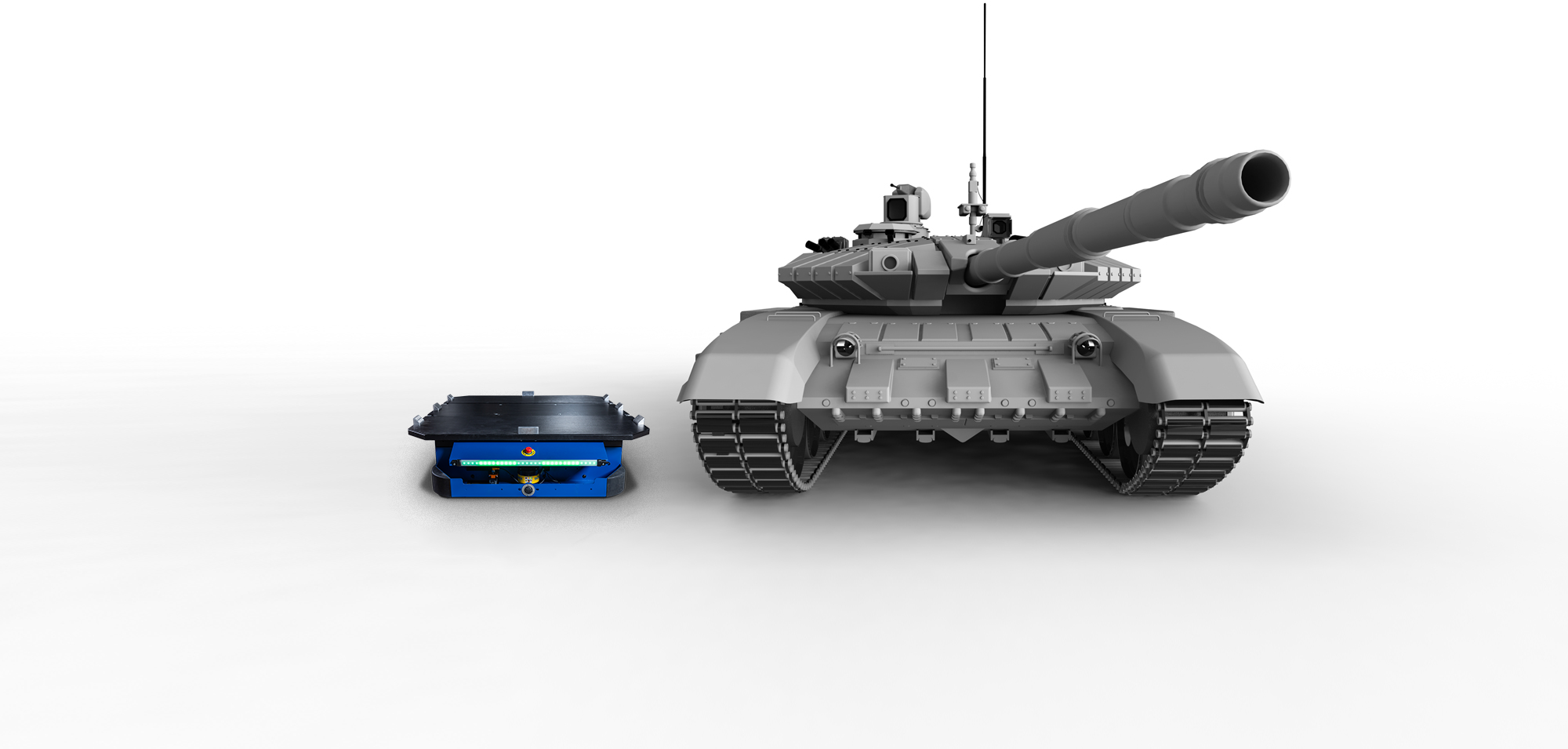

Fred AGVs are built like tanks—inside and out. Despite requiring far less maintenance, they can outlast forklifts, tuggers, conveyors, AMRs, and other AGVs.

- Powered by the industry’s most robust wheel drives to decrease maintenance, breakdowns, and downtime

- Heavy-duty steel construction and smart design makes them nearly impervious to damage

- Super-strong, large, long-lasting wheels easily handle the rigors of repetitive motion

Safety

Fred AGVs drastically reduce the common risks associated with moving materials. Each includes the same intelligent features to keep your workers, products, and facility safe.

- Handles dangerous tasks to help reduce workers’ compensation claims

- Safety lasers scan for objects or people in their path to bring the AGVs to an immediate stop

- Blue lights and audible beeps announce travel direction and presence

- Adjustable speed controls for enhanced safety

- Reduced or eliminated forklift and tugger traffic create a far safer work environment

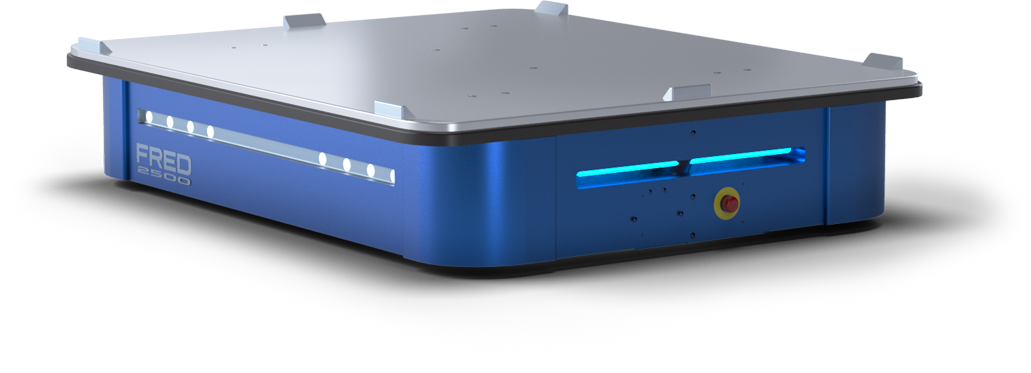

Specs & Options

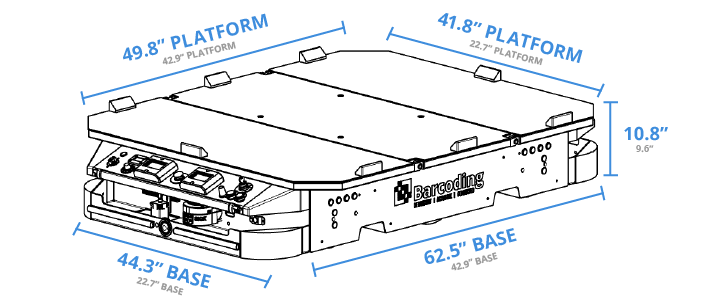

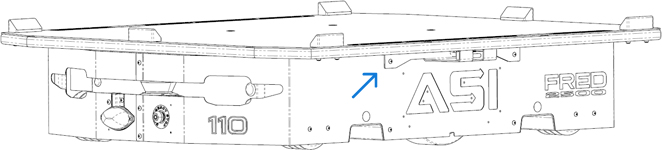

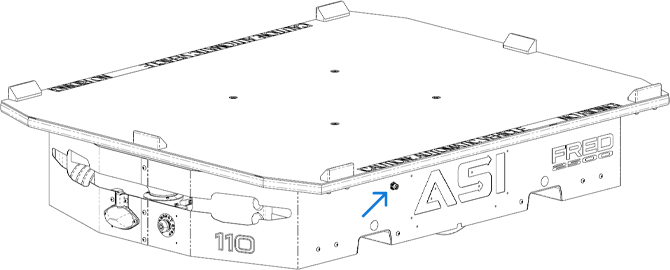

- 630 lb. empty weight; 2,500 lb. max payload; 5,000 lb. max tow load

- 62.5” (L) × 44.3” (W) × 10.8” (H) with top plate

- Up to ~1” ground clearance for use on uneven floors

- Two 12V AGM batteries standard

- Standard platform for 40” × 48” & euro skids for easy loading

- Bidirectional for operational flexibility

- 200 lb. empty weight; 400 lb. max payload

- 42.9” (L) × 22.7” (W) × 9.6” (H) with top plate

- Up to ~1” ground clearance for use on uneven floors

- Two 12V AGM batteries standard

- Bidirectional for operational flexibility

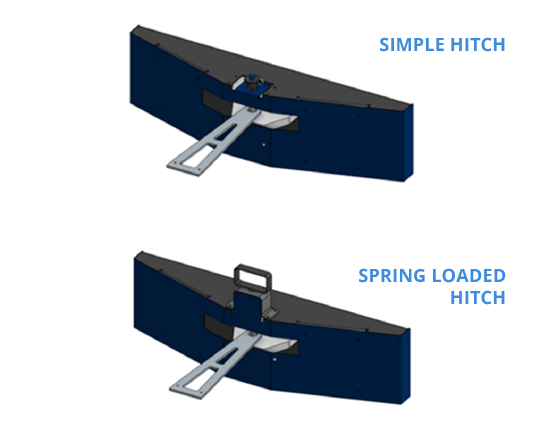

The towing option allows Fred to tow loads of up to 5,000 lb. depending on dolly capacity. This option also enables the quick removal of loads without needing to wait for an available forklift.

What’s IncludedThe towing option uses one of three available hitches (depending on the application) to hold the dolly and/or cart tongue to the hitch on FRED. Dollies and/or carts are available in diverse sizes to suit your needs.

Available Hitches- Simple Hitch

- Spring Loaded Hitch

- Quick Release Hitch (coming soon)

With contact charging, you never need to worry about keeping Fred or Compact Fred juiced up and ready to go. Contact chargers allow for automatic charging whenever stopped at charging locations.

What’s IncludedContact charging includes a collector mounted on the side and/or bottom of Fred or Compact Fred, a floor pad, and a plug-in charger. The charger plugs into a 15A minimum AC power outlet. No power will flow to the contact pads until the AGV connects and the charger detects a battery ready to be charged.

Use CaseContact charging is ideal in a 3-shift operation. The contact charging location should be selected so Fred or Compact Fred spend the majority of their idle time on the charger. You may also want to use contact charging to ensure they’re automatically charged for a 1- or 2-shift operation. In this case, you want to be sure they stop at the charging location for the full length of any unused shift. It’s possible to install multiple contact chargers if you’re unable to ensure the AGVs can stop at just one location.

We have a bevy of sensors for detecting practically any condition within your AGV operating space. Customizable logic can then be set for both Fred and Compact Fred to react to the change in state. WIFI and non-WIFI communication protocols are available.

What’s IncludedPart presence kit that can handle up to 4 sensors and customizable sensor condition setting software.

Common Conditional States:- Object Presence: A pallet or crate is now available for pickup. Conversely, a pallet or crate is needed at a location that is “empty”.

- Fill State: A container has been filled or emptied and is ready for pickup/drop-off.

- AGV Parked: Fred or Compact Fred in a pre-designed parking/que space and is available or not available.

- Traffic Control: Stop/Start Fred or Compact Fred. Conversely, communicate to personnel to an approaching Fred or Compact Fred (traffic light).

Fred or Compact Fred can always be added to an existing WIFI infrastructure. However, WIFI can be spotty particularly in larger facilities. Additionally, WIFI command and control systems means much more complexity and cost. By installing our contact, I/O kits at critical way/decision points within the operating space of Fred or Compact Fred you can communicate with Fred and command it and/or gather onboard data.

What’s IncludedContact I/O kit. Utilizes similar contact technology as a contact charging option.

Complexity Levels:- Basic: Up to 8 one-way (to robot) discrete commands

- Professional: PLC Ladder Logic two-way (to robot/from robot). Sequencing left-hand rail to right-hand rail and from first to last rung.

- Enterprise: Can Bus (Can Open) two-way (to robot/from robot). Sequencing multi-threaded and/or piped state machine.

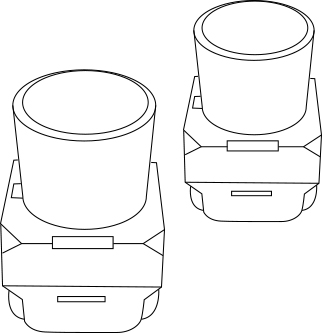

Wireless control buttons duplicate the functionality of the buttons on either end of Fred or Compact Fred, but can be triggered from up to 100 meters away.

What’s IncludedAll you need is a wireless START/STOP button. Buttons are available in an assortment of colors. One wireless receiver is mounted on Fred. Contact us for details.

OperationButtons will come from the factory preprogrammed to control either Fred or Compact Fred. Different colors can be set to trigger different directions of travel. The buttons are designed for line-of-site operation. There’s an indicator light on the button which will flash green if Fred or Compact Fred receives a good signal, yellow if a weak signal, and red if no signal. If the indicator light flashes red, reposition the button or move closer to either AGV and press again.

Increase productivity. Reduce costs. Optimize your facility.

And gain a powerful new competitive edge. Achieving automation's full potential—and blazingly fast ROI—has never been so easy.

Top 10 AGV Myths Debunked: Get the Facts on AGVs

What’s getting in the way of automation and optimization in your manufacturing or warehouse facilities? It could be as simple as changing your mindset and giving up on a few outdated myths.

Download